charpy impact test example|charpy impact test calculation table : distributing Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTM

Resultado da Março de 2024. 02/0316:00. Campeonato PaulistaRodada 11Neo Química Arena. Corinthians. Santo André. 10/0316:00. Campeonato PaulistaRodada 12Distrital do Inamar. Água Santa. Corinthians.

{plog:ftitle_list}

webVocê pode baixar o aplicativo 9F Game em praticamente qualquer dispositivo iOS ou Android. O aplicativo móvel oferece funcionalidade completa, permitindo que você faça apostas, jogue slots, deposite dinheiro, receba bônus e retire seus fundos, mas em um formato mais conveniente. Recursos principais: Características. Dados.

charpy impact test sample

For example, when testing steel for use in cold climates, the ASTM A370 Charpy impact test can reveal how the material’s toughness decreases as temperatures drop. This information is vital for ensuring that the steel won’t fail under cold conditions, as brittle materials are more prone .The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa.

Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .

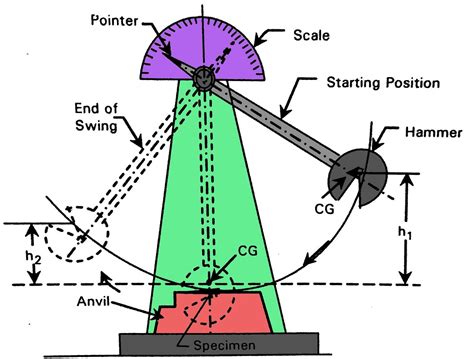

Figure 2-1: Charpy impact tester, sample positioned in anvil and general testing results. This test has been used almost exclusively with body-centered-cubic (bcc) crystalline materials. These .

Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTMThe impact strength (also referred to as notched impact strength) is determined through Charpy testing, and provides information on how resistant a material is to an impact load, or how well a material can handle an impact without breaking. The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is .

The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .

Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. Impact testing is required for many critical applications in the construction, machinery and equipment, defense, and energy markets. Charpy testing provides data needed to ensure the quality and reliability of structural .

The Charpy impact test, sometimes called a V-notch test, is a comparative-style test used to define a material’s impact strength by determining how much energy is required to fracture a pre-prepared and standardized .Introduction to Charpy Testing Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTM . sample to be tested placed in the path of the hammer’s swing, with the notch facing away fromExample of Charpy impact energy measurements. The specimen was a "high-strength low-alloy" steels ; the yield strength curve (YS) obtained by tensile testing is also shown for comparison. We have three series of tests with 8 specimens per series to get statistically significant data.For example, when testing steel for use in cold climates, the ASTM A370 Charpy impact test can reveal how the material’s toughness decreases as temperatures drop. This information is vital for ensuring that the steel won’t fail under cold conditions, as brittle materials are .

Sample preparation: is done by cutting the material in standard sizes. The edges are . smoothened and the surface is flattened. A notch . The Charpy impact test, just like any impact testing .Experiment 7: Charpy Impact Test Name: Om Prabhu Roll Number: 19D170018 Objectives: (a)To study the impact resistance of metals using impact testing machine of the Charpy type (b)To determine the variation of impact strength of a material with change in temperature Experimental Method:

charpy impact test procedure

Figure 1. Charpy Testing Machine The hammer (pendulum) from the machine was pulled up high and anchored. We then obtained a stainless-steel specimen that has been cooled down to -78°C and place it under the Charpy testing machine. Once taking the sample out to room temperature, the experiment must be conducted under five seconds to reduce the .The Charpy impact specimens of each material are immersed in a bath for 10 minu tes to reach thermal equilibrium at five separate temperatures ranging from 110oF (-79oC) to 212-oF (100oC). The specimens are quickly transferred to the Charpy testing machine, fractured, and the impact energy is measured. AfterThe Charpy test is a pendulum-based test introduced by Georges Charpy and S. B. Russell. The test was valuable in understanding the material fracture in ships during world war II. The Charpy test consists of a pendulum and a hammer of known mass attached to it. The pendulum swings and hits the notched specimen to observe the energy transfer.The Charpy impact test is performed to evaluate the resistance of the metal to breakage by flexural shock or impact load according to standard test method ASTM D6110. . The hammer is released from the initial height downward towards the sample. Observations and the energy absorbed are recorded and tabulated. Steps 1-3 are repeated for another .

Charpy Impact Test is the most commonly used test which is used for determining the amount of forces that are absorbed by materials when it reaches the point of fracture. . The pendulum is dropped from a specific height to put an impact on a notched sample. The notch used in the test must be of regular dimensions as it has a great impact on .

A Charpy test determines the impact toughness of metal samples by striking them with a swinging mass. The traditional test method requires measuring the difference between the height of the striker before and after impact. . Methods have been developed to improve upon this, for example by taking advantage of the absorbed energy measurement in .CHARPY IMPACT TEST ISO 179 Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the . • Impact geometry—shape and dimensions of the sample and the impact device, as well as the angle and direction of impact. • How the sample is prepared / fabricated .For example, flexible polymers have an high -impact behaviour due to the fact that the large segments of . Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test. This test, on the contrary of Izod andBy doing this, it is possible to characterize how much energy different materials [with same size] can absorb. Charpy Impact Test Unit Fig. 1: Mechanical principle of the Charpy Impact Test device [2]. Results gathered from the .

Hence, a toughness test is usually conducted using a sample with a notch. Moreover, un-notched samples can also be used for the toughness test and the results are expressed accordingly. a) Notched and Unnotched Charpy Test; b) Notched and Unnotched Izod Test (Source: ScienceDirect) These tests can be used as a quick and easy quality control check. An Izod impact testing apparatus — which is essentially identical to a Charpy impact testing machine — is used to determine Izod impact strength. The primary differences between the Izod and Charpy impact tests are the size of the test specimen, how it is restrained, and which side is struck by the pendulum hammer.

Impact geometry—shape and dimensions of the sample and the impact device, as well as the angle and direction of impact. How the sample is prepared / fabricated (molded, extruded, or machined). Sample-notching procedure. Sample mounting in the tester. Charpy Impact Test ISO 179. Charpy Impact is a single point test that measures a materials . Charpy impact test standards. ASTM E23, ASTM D6110, ASTM A370, ASTM D256. ISO 13479, ISO 148-1. EN 10045-1, EN ISO 179-1 Izod impact testing. While Charpy impact testing is widespread for metals, Izod impact testing is more often used for plastics and other softer materials. In Izod testing, the notched specimen is positioned vertically instead . Determining the sample dimensions The sample shape required to perform a Charpy test is very simple. The samples are rectangular in size (measuring 127mm in legnth and 12.7mm in width) and have a nominal 12.7mm thickness. They feature a 45-degree V-notch with a 2.54mm notch radius. Mounting the specimen in the testing machine

specimen to the deforming or breaking specimen is equated to the "impact energy." The Charpy impact test uses a standard Charpy impact machine to evaluate this impact energy. The machine consists of a rigid specimen holder and a swinging pendulum hammer for striking the impact blow to a v-notched specimen as shown in Figs. 1 and 2.

The following table, Table 6., shows the energy absorbed at a certain temperature during the impact test for the set of sample in the high temperature oil bath. Table 6. Impact Energy Absorbed for AISI 1045 High Temperature Oil Bath. Specime n Temperature, T, oC Measured Impact Energy, EIM, ft Converted Impact Energy SI, ESI, J 1 151 30 40. 2 .

Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. The specimen is usually in the form of a thick beam with or without a notch and is supported freely at two ends, as shown in Fig. 3 (a).The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient .The Charpy impact test is still used throughout sectors to assess material toughness, from construction and manufacturing to engineering and beyond. This test offers practical insights into how materials respond to sudden, dynamic impacts. Even as businesses change, the Charpy impact test is still a valuable and essential tool.

Neste artigo, vamos explorar como funciona a primeira consulta de uma vidente online grátis e onde encontrar esse serviço. Uma vidente pode usar diferentes técnicas para ajudar a descobrir o que está oculto. Elas podem usar a leitura de tarô, a leitura de auras, a leitura de mãos e muito mais.

charpy impact test example|charpy impact test calculation table